Manufacturing companies face complex conditions, fluctuations in supply and demand and rapidly changing demands. If demand in a particular market declines, you have to respond to it. For organizations, this is a major challenge that requires complete control over production. SAP Manufacturing Integration & Intelligence (MII) is the solution for this!

What does SAP MII mean?

SAP Manufacturing Integration & Intelligence (MII) is a direct connection between the machines on your shop floor and the operational (ERP) systems within your organization. All data relevant to your production process is accessible in real time. Information about orders, materials, the status of your equipment, costs and product quality are also available. SAP MII leverages IoT, computer-integrated manufacturing and machine-to-machine (M2M) features.

How does SAP MII work?

As the name implies, SAP MII consists of two main components:

- The integration component uses Web standards to link SAP ERP and related business applications to plant applications. It uses Web server technology to extract and merge data from multiple sources. It can also be accessed from different devices. Combined with SAP Cloud Platform Integration and executed on the HANA in-memory database, SAP MII can help enable global visibility into manufacturing operations.

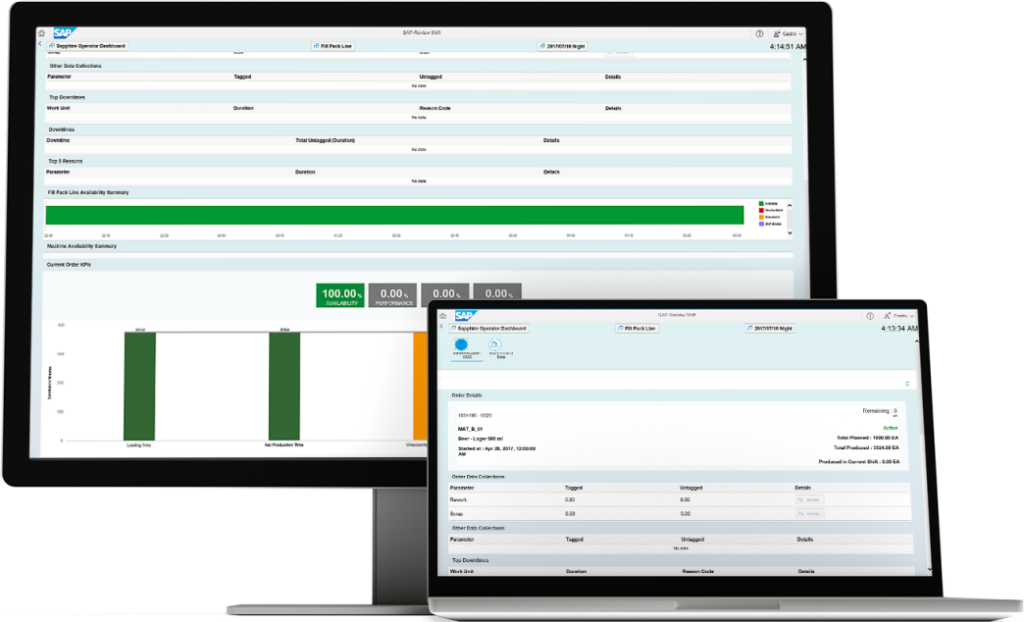

- The intelligence side is designed to provide real-time analytics of production activities, using visualization tools and dashboards to display key performance indicators (KPIs) and alerts. Operations managers, company executives, plant employees and suppliers can use these functions to make short-term production decisions.

Benefits

SAP MII realizes the vertical integration between topfloor and shopfloor. With SAP MII you will achieve your production goals and realize cost savings, quality improvement and better utilization of your machinery. In addition, you can integrate business processes and master data into your production processes so you can do your business based on one version of the truth. In this way, you have instant visibility over the total plant floor and higher asset utilization rates through continuous optimization.

- Monitor production and measure and control Key Performance Indicators (KPIs).

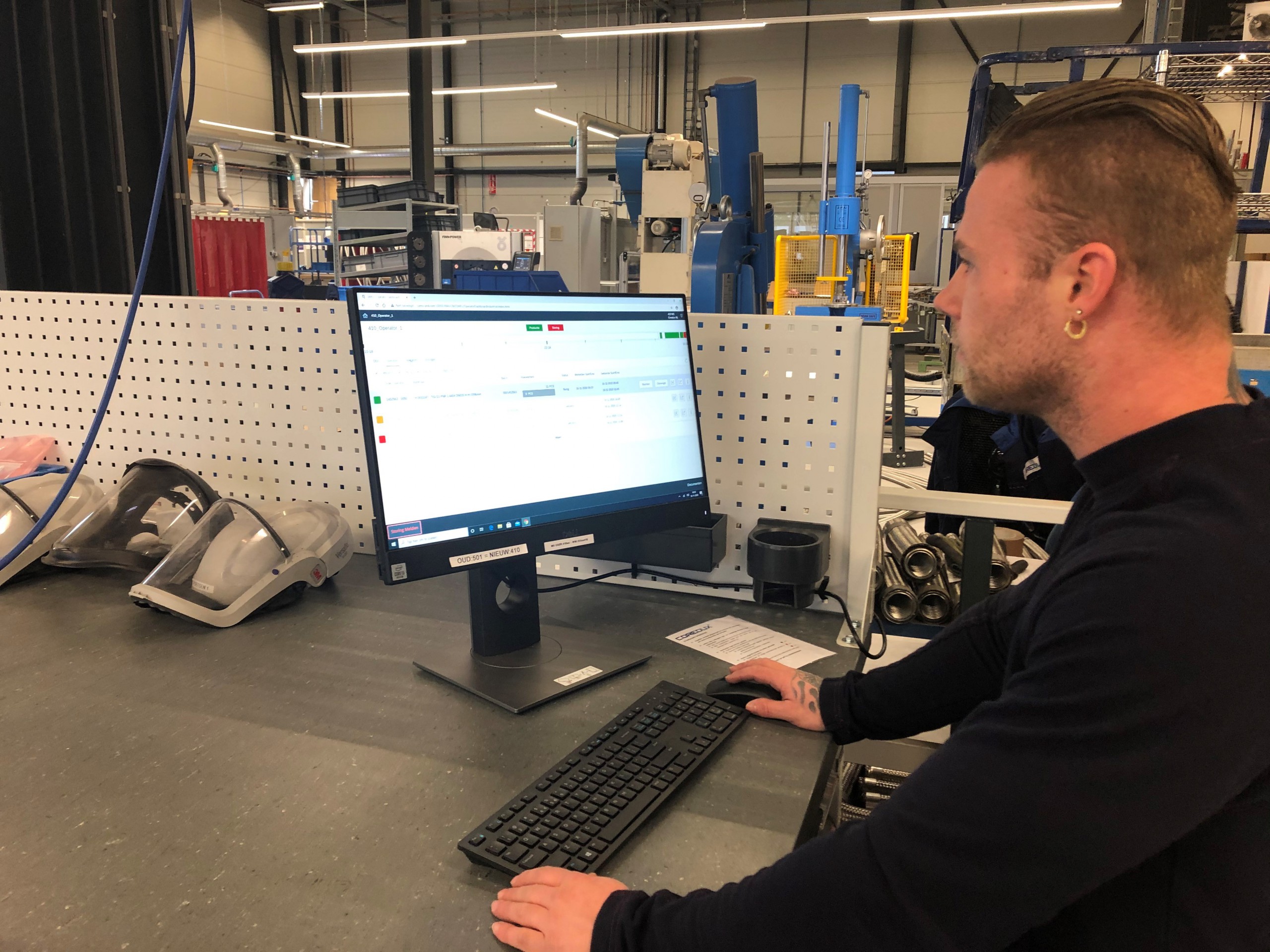

- Real-time exchange of data between shop floor and ERP environment.

- Realize collaboration between parts outside and inside the ERP environment.

- Provide production personnel with real-time decision support so that they can respond to exceptions and meet objectives.

Carlisle halves production time from 10 to 5 days through perfect teamwork with Quinso

“Efficiency on the production floor has increased dramatically,” said Rob Reeve, Managing Director of Carlisle Hardcast Europe. “Thanks to Quinso, we now have a robust foundation for Lean Manufacturing.”

Our customer stories

We see that organizations are now taking important steps in providing insight into real-time data in their organization. We are happy to help you optimize your business processes with an integrated solution within your SAP system. So if you want to know more about us, our company or solutions: we are here for you! Take a look at our customer references!

Jurgen de Jong

Our broad knowledge

A broader view is also needed? If so, please feel free to contact Jurgen de Jong. He knows the latest technological developments of shopfloor automation with SAP MII and Integrated Smart Manufacturing.