‘It’s like losing weight. You bring in a doctor, a dietician, a psychologist, you start exercising…. But to actually take that next step, you really have to get started yourself’. With this metaphor, Hubert Wezenberg, managing partner at Quinso, opened the Quinso event Becoming an Intelligent Manufacturer on Wednesday, Jan. 22 .

Becoming an Intelligent Manufacturer. Is the manufacturing industry that stupid then?

There is no question that the (manufacturing) industry is smart. In less than 250 years, we have evolved from steam engines to fully computer-controlled manufacturing systems, robots, automated transport systems and 3D printing. Industry 4.0 allows us to further increase productivity while delivering more and better custom products.

Simpler said than done. Every day I speak to clients struggling with this challenge. Using three elements-technology, process and people-I take them on a journey. I let them see and experience what it takes to break patterns. How to start thinking differently and become even smarter by working together and learning from each other with the technology that is available. Last but not least, how you include your entire organization, your people, in that.

To help companies who are open to doing so take a step further, Quinso organized the event. For one day, our office served as an incubator for manufacturing managers, SAP specialists and supply chain managers from the manufacturing industry. ‘So how do I become that smart(er) manufacturer, am I ready for Industry 4.0, what does it take?’ In this blog I look back on the event and share 5 eye openers that will enable us to work even smarter, with each other:

1. Industry is more than technology

The first eye opener comes from Kees de Schipper, Industry Sector Specialist Rabobank: Industry is more than technology. Industry is also revenue development, productivity, personnel costs, innovation, future-proofing and investment.

The manufacturing industry has also landed in Industry 4.0! This requires new investments. In personnel, resources but also developing technology. In the past, investment often did not lead to the desired results. Rabobank conducted research into causes of this last year, says Kees de Schipper. ‘We surveyed 16,000 customers. With the results of the survey, we will engage with them in the coming period about Where to make investments, and How to make sure you become as successful, sustainable and future-proof as possible. Many times it starts with: delve into current trends. What is hot, and what are we going to say goodbye to in the coming years? Based on that, make a plan.

Source: presentation Kees de Schipper, January 22, 2020

2. Benefits and pitfalls of a best practice SAP implementation.

Another trend: working in the Cloud. More and more companies are taking the plunge and choosing a best practice SAP implementation. Jilt Bakkes, Managing Partner at Quincept, listed the benefits:

- high degree of standardization

- process simplification

- lower implementation costs

- low maintenance costs à no customization

- periodic upgrades (Evergreen model – Cloud) à the customer does not have to worry about this

- Customization remains possible à in the shell around it

Lessons learned

There are also pitfalls, such as eye-opener number two: “Cloud implementation is a fast-paced process. Your people have to be able to keep up. Therefore, be critical,’ Jilt Bakkes warned. ‘Put your best people on the project. Those who can handle it mentally and don’t get stuck in old systems. Or even better, hire new people. And remember, it requires a lot and clear communication, and change management is also indispensable. You will have to make concessions. It’s a true journey, a long-term collaboration!

3. The SAP Experience Center makes digital innovation a reality

Mid-day, we visited the SAP Experience Center, where Michael Blokdijk opened by saying, “When I tell people on birthdays that I work at SAP, people often associate it with big, expensive and those user-unfriendly blue screens. What it can really do for your business is not clear to many. That’s why there’s the SAP Experience Center, to let people experience what’s possible with the software and how you can use it to grow your business (eye-opener number three).

3 cases were covered, all supported by SAP software:

- The Intelligent Coffee Experience, which through the collection of data provides customers with services and offers that precisely fit an individual organizational need

- Smart packaging center, where machines can be easily and quickly repaired using augmented reality in the event of a breakdown. A technician can also watch and give instructions remotely.

- Smart Shelves: using an Ipad to scan products in the store. The screen displays the features and which product types are available. A salesperson is no longer needed!

4. Intelligent Manufacturer? Let’s get soft!

The fourth eye opener: EQ is the answer to good leadership. In fact, research has shown that there is a link between EQ, the ability to respond to people’s intrinsic motivations and abilities, and performance in the workplace. Executives who do have it generally perform better. After all, having empathy for your people creates trust and commitment. In doing so, you become the kind of leader people love to work for.

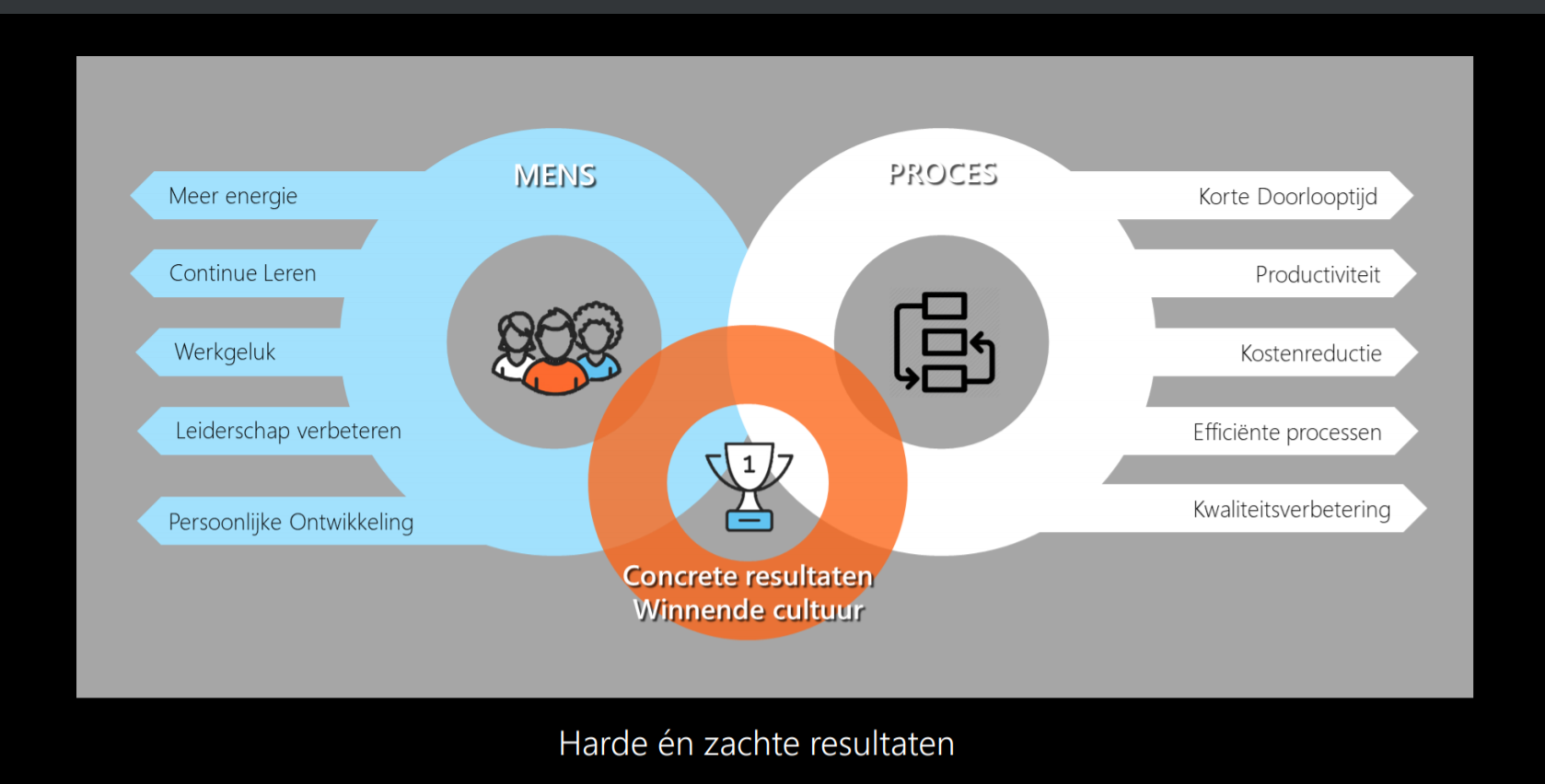

Edwin van der Weele, owner of Tridion: “There is a visible movement from hard, or measurable goals, to soft goals. In many cases, one cannot be done without the other. After all, to improve lead times, quality and costs, you desperately need your own people. Put them in motion. Tell why the improvement (or change) is necessary. Let them experience it. Involve them in the process, give them ownership and show commitment’.

Source: presentation Edwin van der Weele, Jan. 22, 2020

5. Innovation through design strategies from nature

The fifth and final eye opener comes from Saskia van den Muijsenberg, founder of BiomimicryNL: “What humans make is scarce and valuable. Nature uses what there is plenty of, because that takes the least energy. So let’s copy off more often. A lot of functionalities, which we are looking for, can be found in nature.’

You wouldn’t know it, but a peacock’s feathers are brown. So how is it that we see these beautiful colors? This can be explained by the structure and reflection of light, or structural color. The fashion industry already applies this trick to fabrics. Very smart, because it is cheaper (shape is cheap, color is expensive) and produces less pollution.

You wouldn’t know it, but a peacock’s feathers are brown. So how is it that we see these beautiful colors? This can be explained by the structure and reflection of light, or structural color. The fashion industry already applies this trick to fabrics. Very smart, because it is cheaper (shape is cheap, color is expensive) and produces less pollution.

Another example we can learn a lot from is self-organization. Large groups of social organisms are organized in such a way that each individual organism knows exactly what is expected of it. Think of schools of fish, termites or flying geese. It has long been thought that the reason why a different goose always flies in front is due to fatigue. But there is more. Not every goose knows the whole way, but only part of it. Now project this onto your organization. Appoint not one, but rather several project managers. Each according to his expertise. Also make simple rules and let people know that they are complying with those rules, they need that.

Now when are you that smart(er) manufacturer?

Back to the beginning of the day. When are you that “Intelligent Manufacturer,” ready for Industry 4.0? If you ask me, these are, of course, the participants of our event. They understand the developments in the industry and respond smartly to them, which actually grows their business. Second, it is the manufacturers who understand that it takes more than digitalization and technologies. They consider good investments, future-proofing, cooperation (including with parties outside their own industry), getting your own people moving and sustainability to be at least as important.

Ultimately, indeed, it is like losing weight. You have to do it yourself. With your business, AND with your people. Getting smarter is done together, with the technology available today. And then when you take the next step, look at nature first!

The next step

I look back on a very nice event. Engaging speakers, a visit to the SAP Experience Center. Participants were inspired by the program and each other. Are you also wondering if your company is ready for the next step? We’d love to find that out with you. Please feel free to contact me (marc.van.der.zon@quinso.com).

Become an Intelligent Manufacturer too? Go to“Become a Smart Manufacturer.